A Wagonmaster technical specialist will train your technicians and service personnel in the proper use and safe operation of all BG tools and equipment. They will also review applications, chemistry involved, features, and benefits of each product and service.

This revolutionary equipment is all your customers need to solve carbon buildup in new technology engines once and for all. No teardown. No downtime. Just BG. This revolutionary equipment is all your customers need to solve carbon buildup in new technology engines once and for all. BG Platinum® Fuel Service Supply Tool includes a clear canister that allows technician to monitor fluid levels.

Revving the engine is required during most induction services. It’s what propels the product across all cylinders. Without frequent, consistent engine revving, there’s a risk of hydro-locking the engine during a service. The new BG Rev-It,® PN E101-2110, revs the engine automatically so techs are free to safely perform other services while the service is running. The BG Rev-It® ensures optimum cleaning ability of all BG induction services, including the BG Platinum® Fuel System Service. Take the labor out of labor hour with the BG Rev-It®!

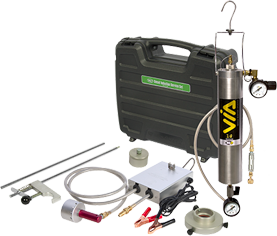

BG Diesel VIA® provides a quick and simple means of delivering the exact amount of BG Diesel Care, PN 229, needed to clean deposit clogged injectors. Connected directly to the fuel supply and return lines, it removes combustion deposits that rob a vehicle of performance. Features of the BG Diesel VIA® include: two-quart/liter canister, can be pressurized by any air source and transported to the vehicle, and it can be pressurizes up to 30 psi.

BG Diesel ISC® Induction System Cleaner™ is formulated to liquefy and remove even the most stubborn oil deposits and unburned fuel formed by EGR and PCV gases as they pass through the air intake and intake valves. BG Diesel ISC® will liquefy the deposits allowing them to be burned in the normal combustion process. DPF, catalytic converter and oxygen sensor safe.

The BG Diesel Induction Service Set includes an Injector Adaptor, Throttle Depressor, Timer Box, Air Intake Adaptor and the BG 1Q VIA® supply tool. Using these components, this service sends BG Diesel ISC® Induction System Cleaner™ through the EGR runners and the fresh air intake.

BG PXT®2 Performance Exchange® for Transmissions removes worn-out transmission fluid and accumulated deposits and replaces it with new transmission fluid and conditioner. The BG PXT®2 features: automatic flow correction, adjustable fluid metering control, weight scale balanced metering, quick-touch screen, integrated additive installation, exchange booster for short service time, large storage drawer, wide machine platform, front tool/adaptor tray, single line hookup for quick transmission connection, dual pumps prevent fluid intermixing, and two seven-gallon tanks allow multiple services on one fill.

The BG PF5 removes old, contaminated fluid while simultaneously adding new fluid, permitting no intermixing of fluids. As a part of the BG Transmission Service, the BG PF5 cleans the transmission system using BG Quick Clean for Transmissions, PN 106, and conditions fluid with BG ATC Plus,® PN 310, or BG CVT Plus, PN 303.

The BG CT2 installs new 50/50 coolant into a vehicle’s cooling system while simultaneously removing the old, spent coolant. The BG CT2 can be refilled and emptied with a flip of a switch. Unlike other systems, the BG CT2 has the capacity of transfusing the coolant with or without running the engine. Most vehicles can be serviced with the engine off, thus preventing the common problem of continuous intermixing of new and used coolant due to the closing and opening of the thermostat. This process backflushes the vehicle’s cooling system, removing scale and debris that is not accessible when going with the normal direction of coolant flow.

The BG CT4 uses vacuum to remove spent coolant from a vehicle’s cooling system. When the removal is complete the vacuum automatically draws the new 50/50 coolant back into the vehicle’s cooling system leaving absolutely no air pockets. There is no vehicle disassembly required; the entire service is done through the radiator cap. The BG CT4 uses one service hose and radiator fill neck plug to simplify connections while putting the power of vacuum extraction at your finger tips.

BG’s MVP Coolant Exchanger is universal, convenient and simple to use. This machine offers a convenient alternative to traditional and common drain-and-fill methods. Improve your shop productivity with this new BG machine. BG MVP Coolant Exchanger features include: multi-vehicle platform, compatible for use on any vehicle with a coolant system, no disconnecting and reconnecting between the engine and the machine, handheld dispenser controls the entire service at the vehicle, and no pumps or impellers to replace.

The BG Power Steering Service Center drains contaminated power steering fluid while simultaneously installing fresh fluid. This ensures that all contaminants, wear metals and debris are removed from the without trapping air in the power steering system. The BG Power Steering Service Center can also be used to install BG Quick Clean for

Power Steering, PN 108. The BG Power Steering Service Center features include: exchanges power steering fluid in 15 minutes, control block that allows for precise control of fluid level, uses shop air, and has a five-gallon used fluid container.

The BG Drive Line Service Center provides a fast and easy way of servicing all types of automotive differentials, manual transmissions, manual transaxles and transfer cases in light and heavy-duty vehicles. It is the most complete self-contained machine of its kind on the market. BG Drive Line Service Center features include: a 5-gallon used fluid container, a unique snorkel tube that can switch from removal mode to additive installation mode in seconds, and it can draw fluid from small bottles to 16 gallon drum.

The BG PF7 Brake Service System quickly and effectively removes oxidized and corrosive brake fluid, replacing it with fresh fluid. Features of the BG PF7: exchanges brake fluid in 20 minutes, uses shop air to remove and replace brake fluid, suction wand is used to remove brake fluid from master cylinder, used fluid reservoir, and visual indicator that tells the technician when needs to be refilled.